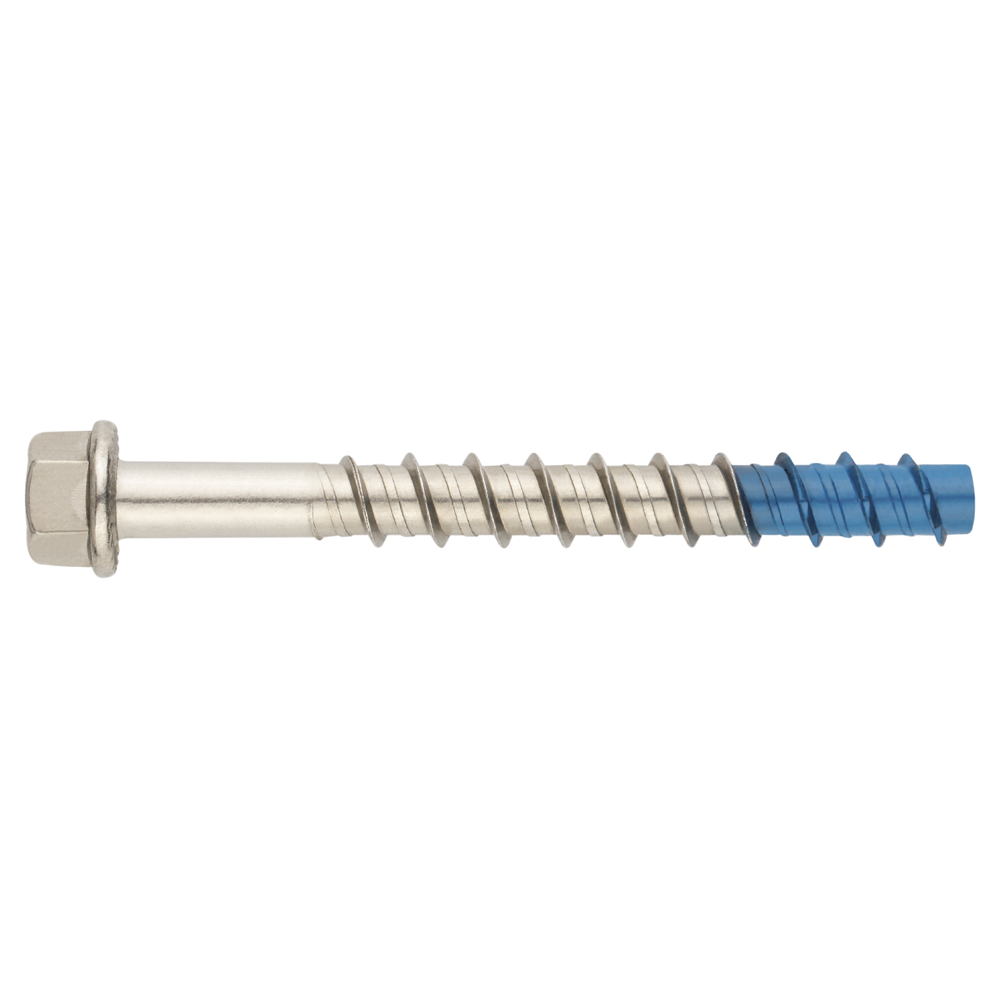

INDEX® Concrete Screw Anchors

Heavy duty screws that are up to 45% faster to install.

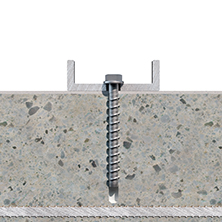

INDEX® high-performance, certified direct concrete anchors are the most effective solution for professionals who need a quick, simple way to install structural and non-structural elements in cracked or uncracked concrete.

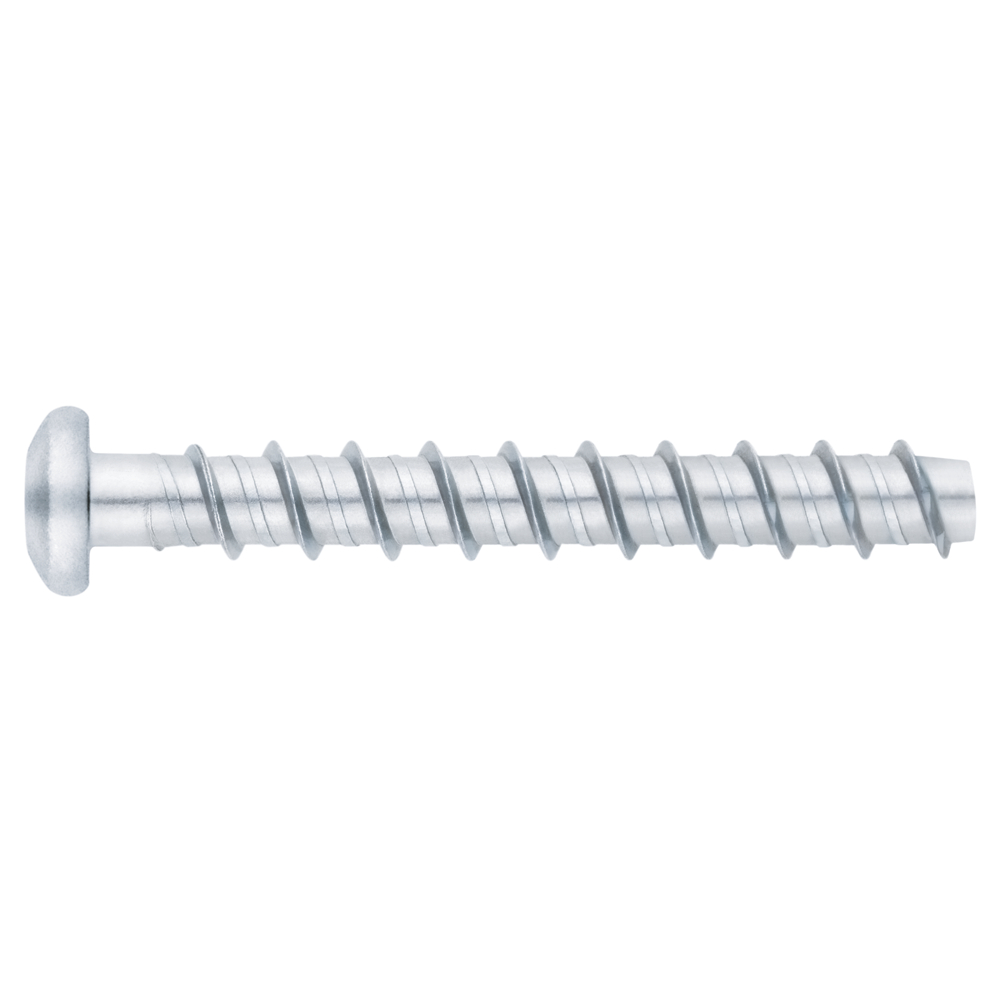

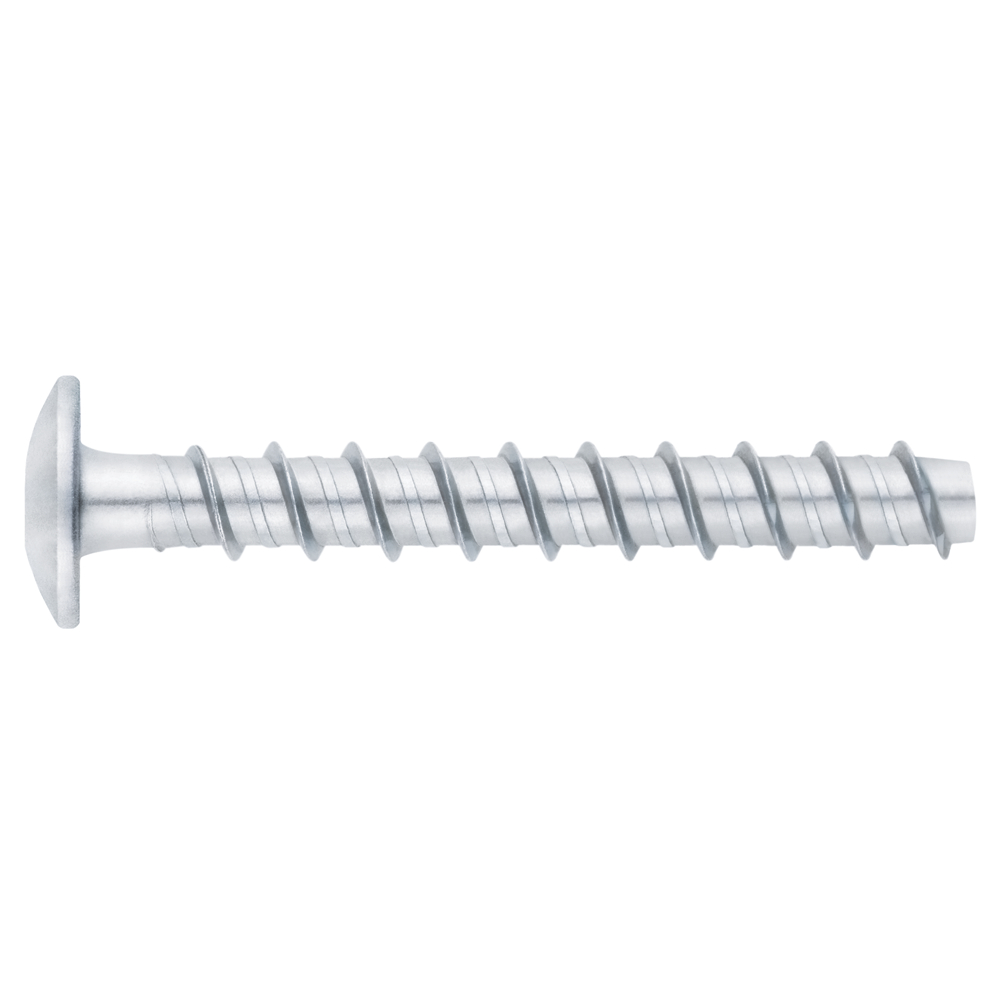

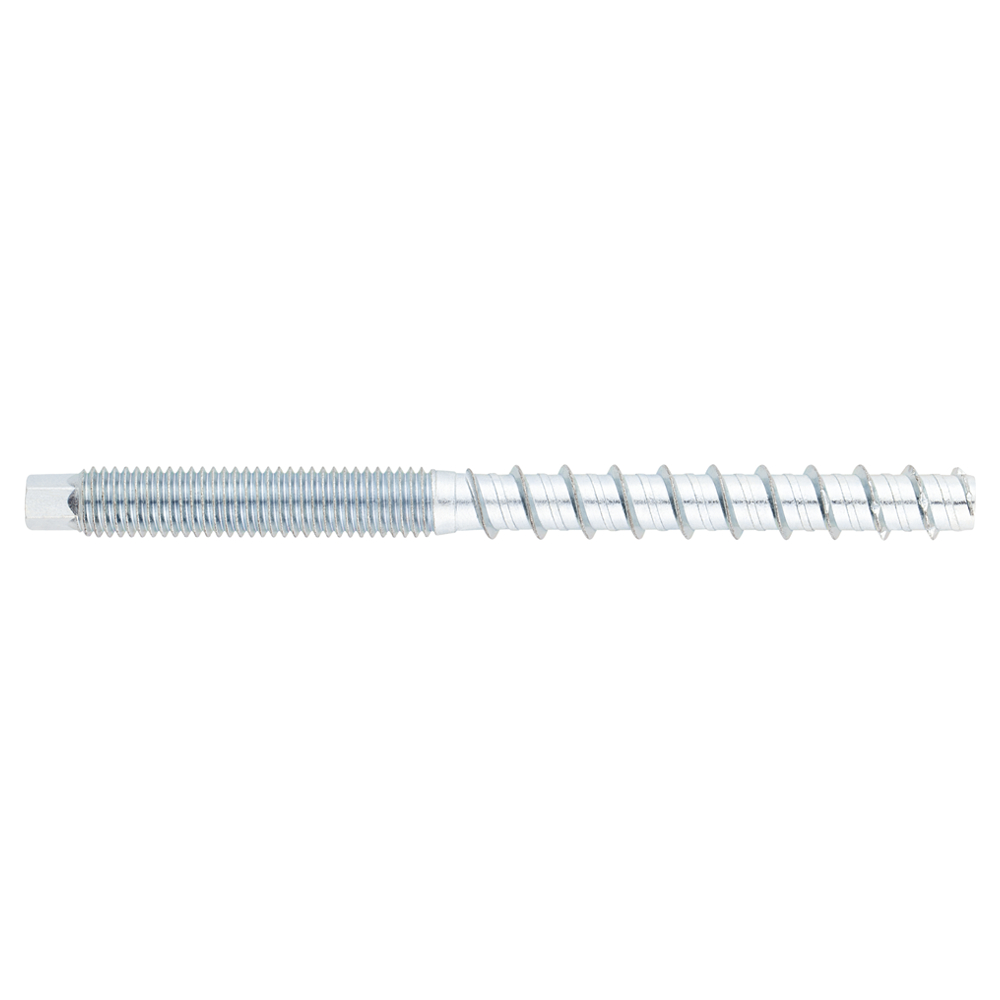

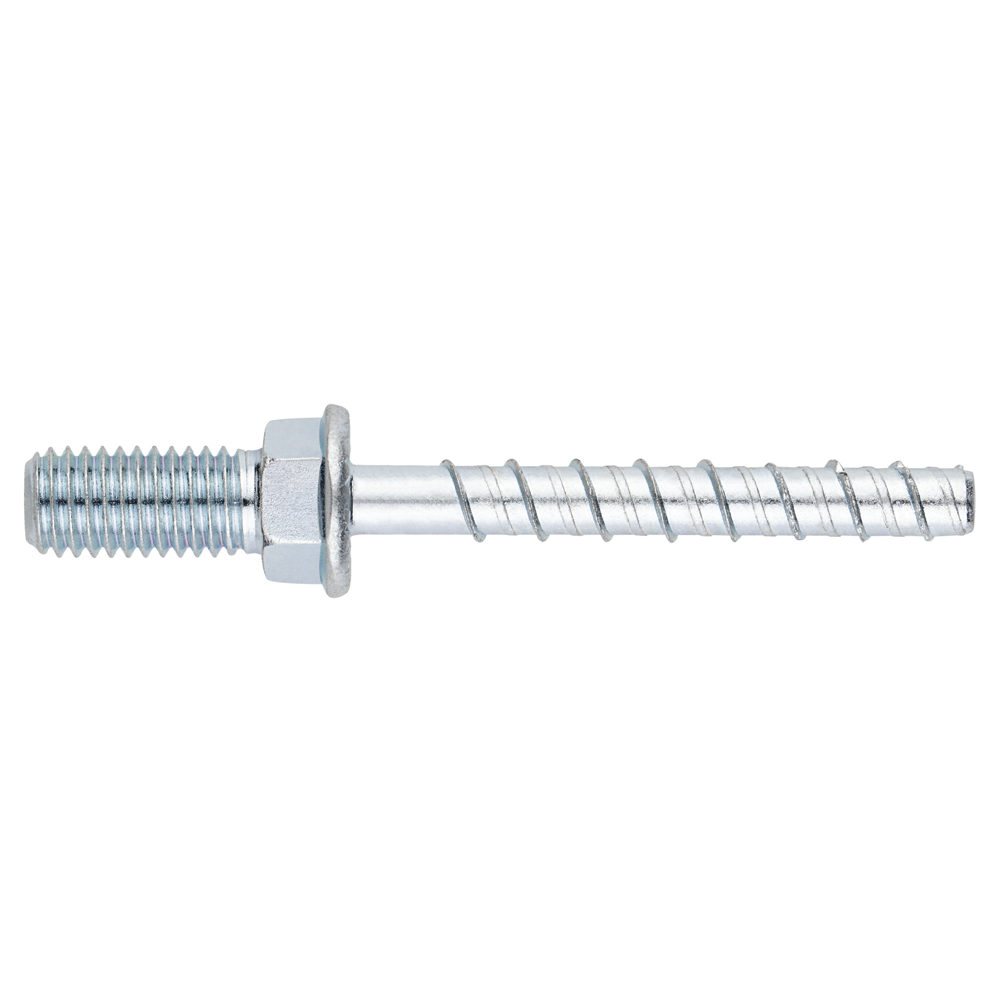

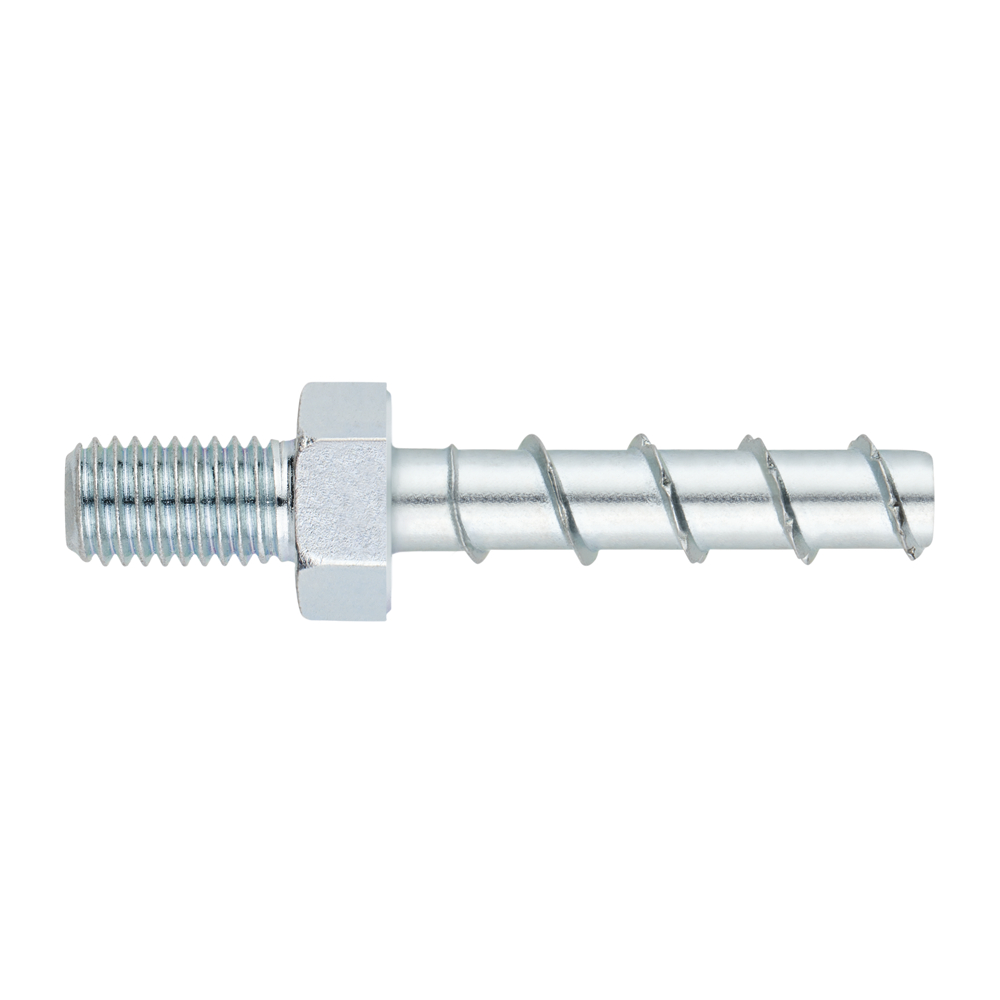

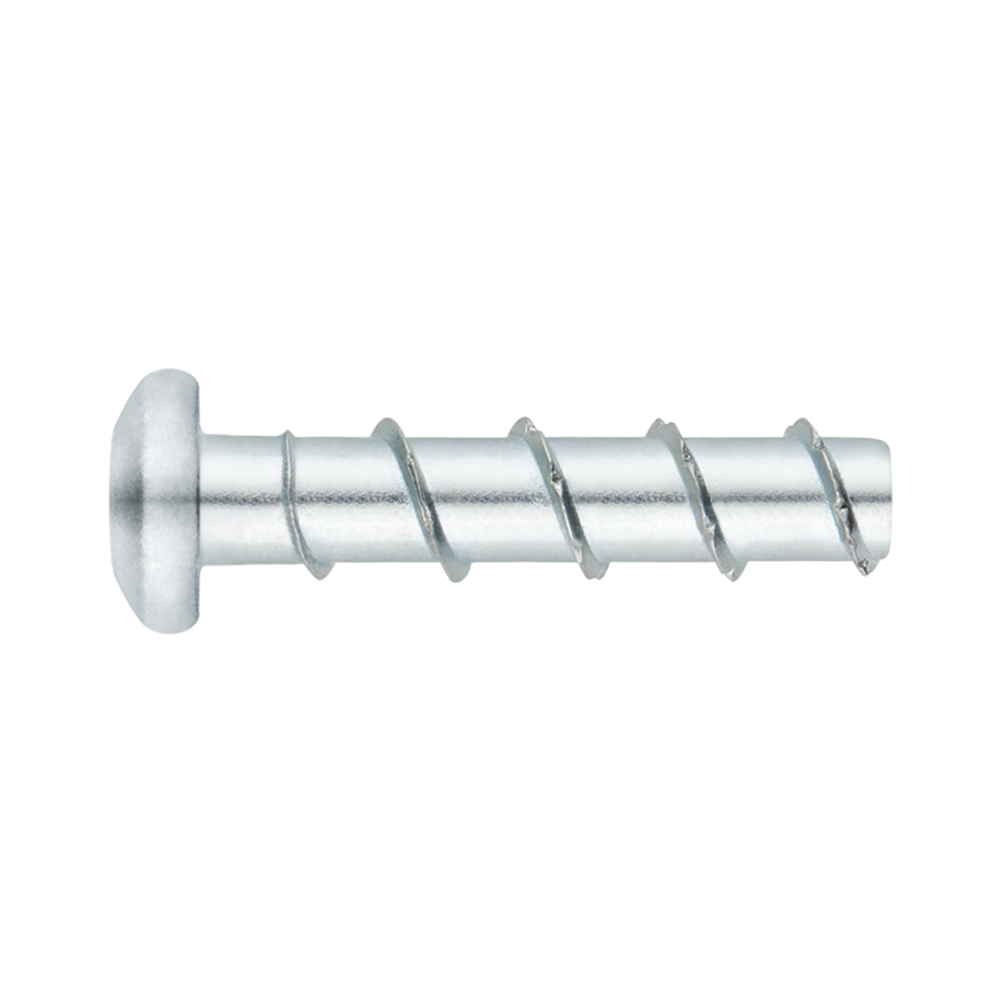

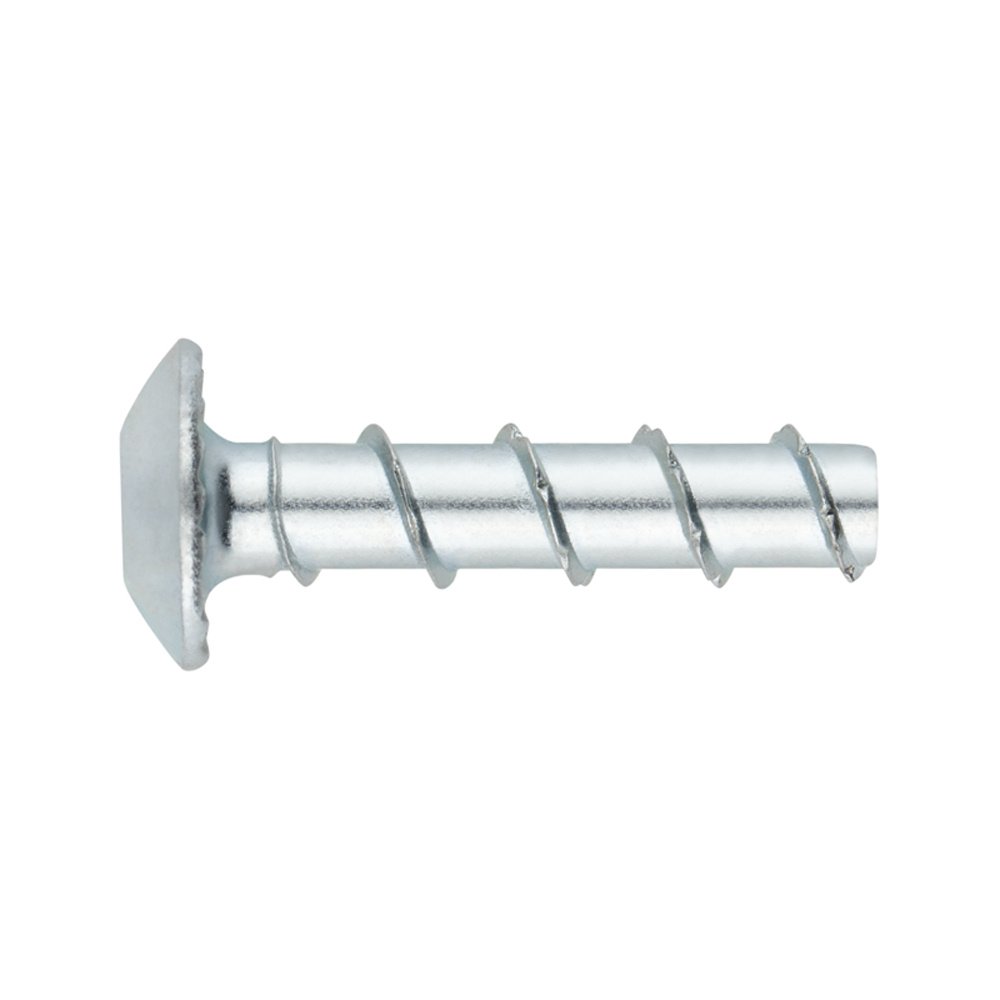

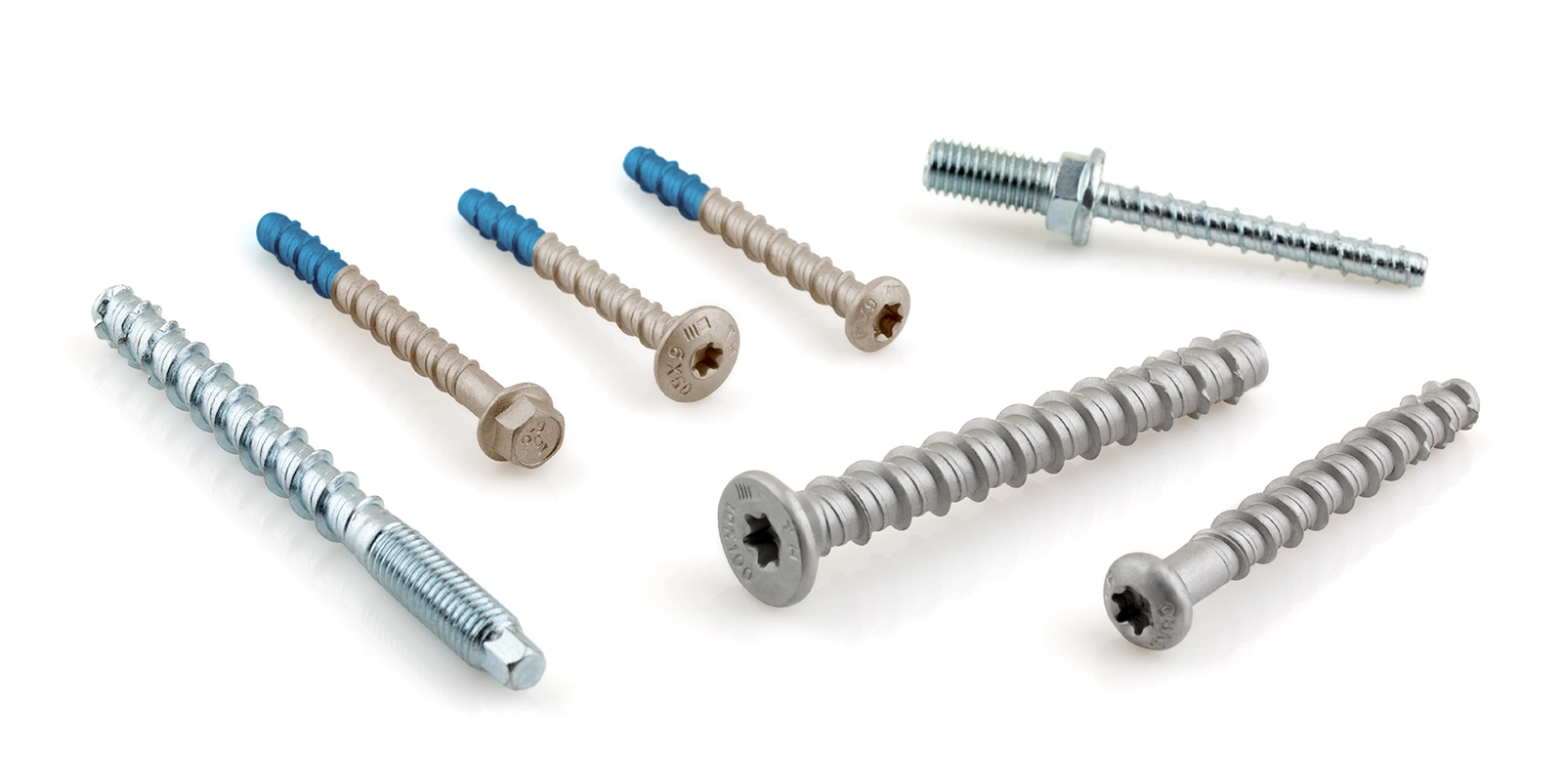

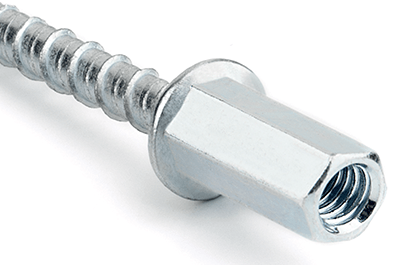

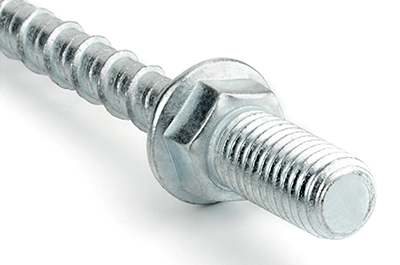

Range of concrete screws

Why are they the best solution? Let's explain.

21 different

varieties available

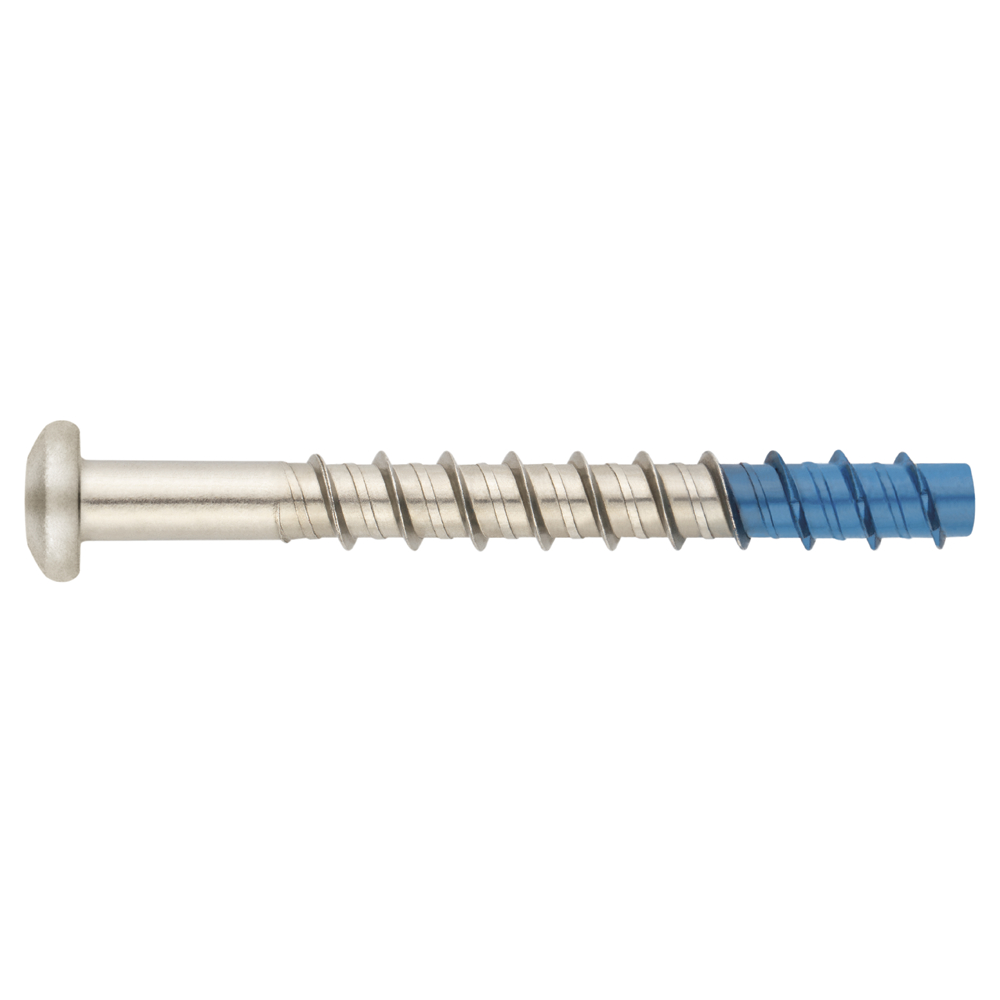

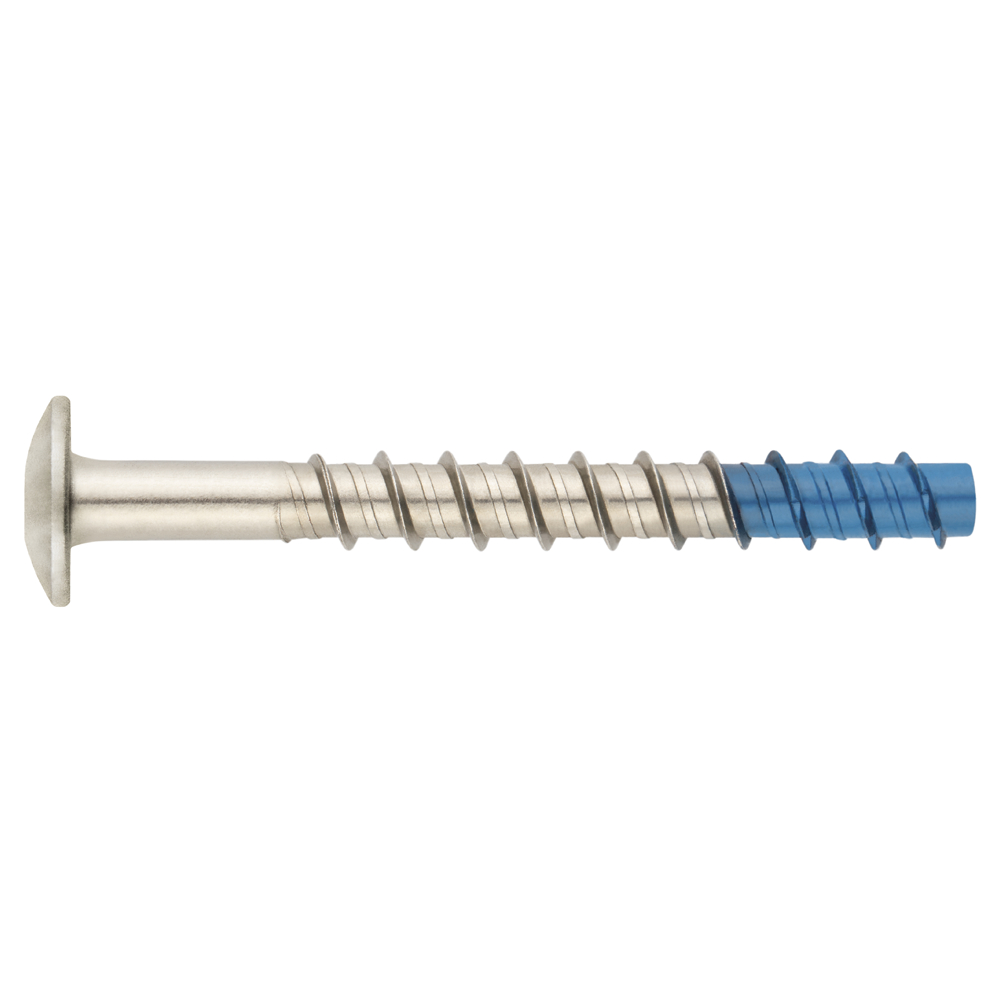

The range includes 9 different types of screw head, 3 surface finishes and various diameters to cater for a diverse range of applications, giving you enough flexibility and simplicity to help you choose the right solution, whatever the project you’re working on. Find out more

Surface coatings for maximum protection

These concrete anchor screws are available in three different finishes: A4 stainless steel, Atlantis C3-H and galvanised ≥5μm. These finishes provide guaranteed protection against wear and corrosion to extend the anchor's useful life, even in harsh environments. Find out more

Greater maximum loads and reduced spacing distances

These concrete anchor screws can support greater maximum loads in cracked and uncracked concrete (C20/25 to C50/60). In addition, they can also be installed closer together or nearer to the edge of the concrete element. Find out more

Up to three

installation depths

These concrete anchor screws can be installed at up to three different depths (Ø6 and Ø10 versions only), providing greater flexibility in a variety of scenarios. Find out more

Fully adjustable and removable

Concrete anchor screws can be loosened to suit the requirements of the element installed and are ideal for temporary installations where a clear surface is needed following disassembly.

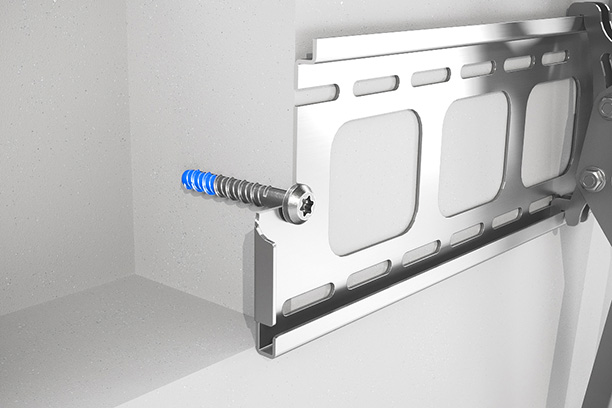

Quick installation for greater efficiency

All you need is a drill and an impact driver. With no need for a torque wrench, they are much quicker and cheaper to install. Find out more

INDEX® quality

guaranteed

Homologated products manufactured under rigorous quality controls, offering you the security and confidence you are looking for. Find out more

Find them

on INDEXcal

If you use INDEXcal, the program for calculating anchor requirements according to Eurocode 2, Part 4, you can quickly and accurately find the details to check which anchor is most suitable for your project.

Maximum quality and safety guaranteed

These concrete anchor screws are certified according to the most demanding industry standards to guarantee secure, reliable fixings, including in critical or high-risk applications.

ETA 20/0046

ETA 20/0046 Option 1 certified for installation in cracked and uncracked concrete (C20/25-C50/60). See technical data sheet.

ETA 20/0494

ETA 20/0494 certified for non-structural redundant systems in concrete (≥ C20/25) and hollow-core slabs (≥ C30/37). See technical data sheet.

Fire resistance

Fire resistance class R30-R120 certification for anchors in concrete.

Sísmica C1&C2

C1 & C2 seismic approval for structural installations at risk of seismic movement.

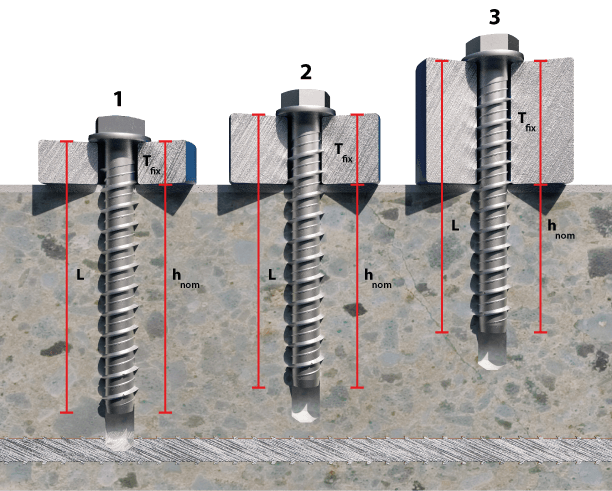

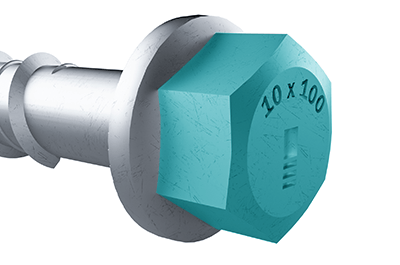

Up to three installation depths

These concrete anchor screws can be installed at up to three different depths (Ø6 and Ø10 versions only), providing greater flexibility in a variety of scenarios.

THE 10 x 100 (example)

| Installation | Fig. 1 | Fig. 2 | Fig. 3 |

|---|---|---|---|

| hnom Installation depth | 85 mm | 75 mm | 55 mm |

| Nrec Maximum tensile load recommended * | 1.342 kg | 1.095 kg | 654 kg |

| Tfix Maximum fixture thickness | 15 mm | 25 mm | 45 mm |

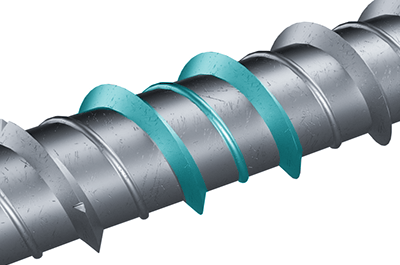

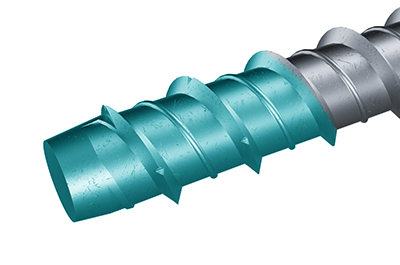

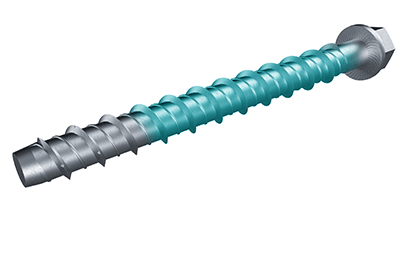

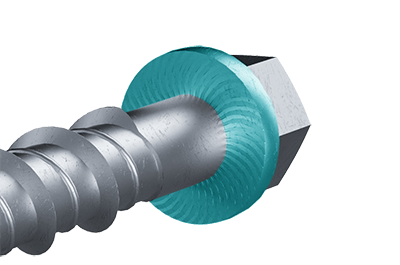

Concrete anchor screw design and geometry

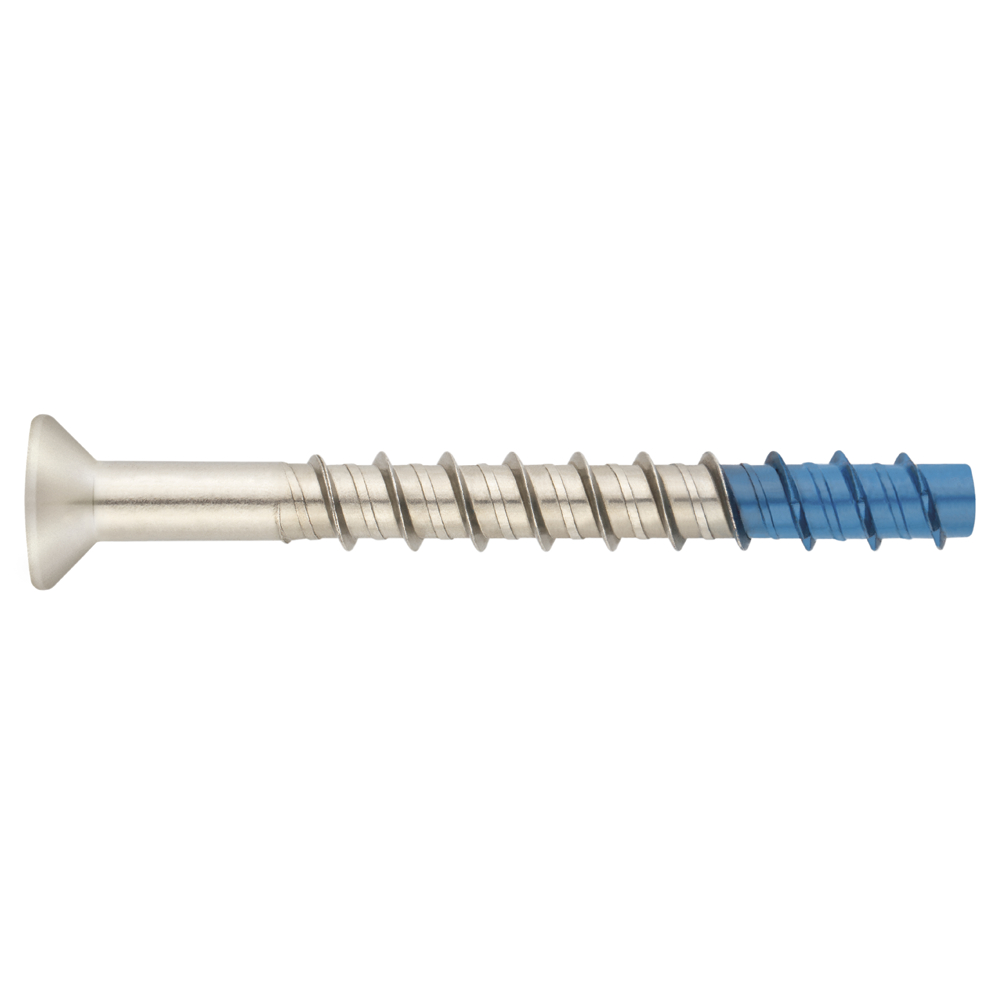

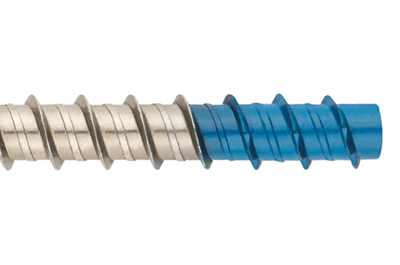

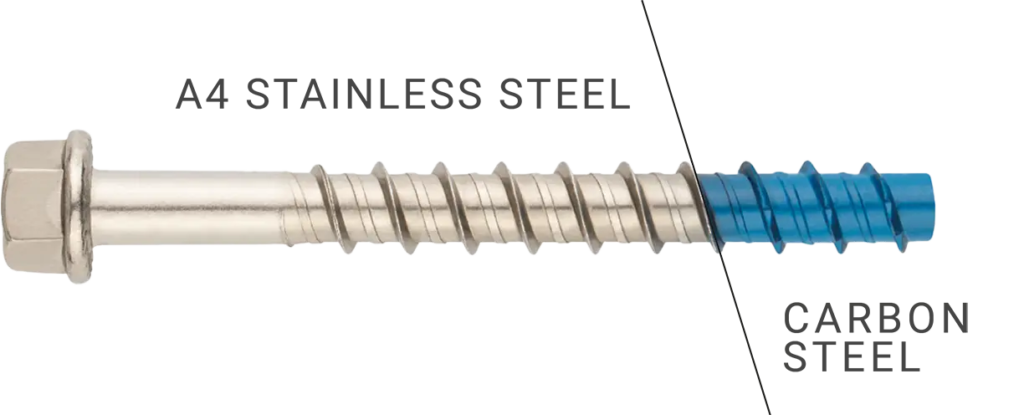

Have you heard of BIMETAL technology?

Anchors made from A4 stainless steel and carbon steel

Our TX models of concrete anchor screw are manufactured using BIMETAL technology, which provides high resistance to both wear and corrosion in situ thanks to the combination of stainless and carbon steel.

Features of A4 stainless steel

Strength of carbon steel

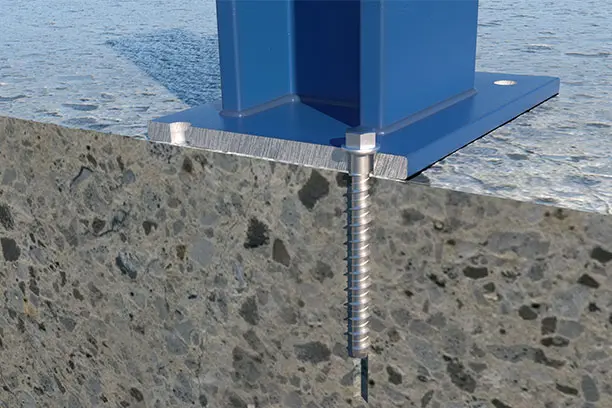

Anchor for fastening structural and non-structural elements

Applications for ETA 20/0046 version (installations in cracked and uncracked concrete)

- Structural applications

- Awnings or temporary signage

- Stadium seats

- Wood to concrete structures Railings and fences

- Shelves and racks

- Structural beams and pillars

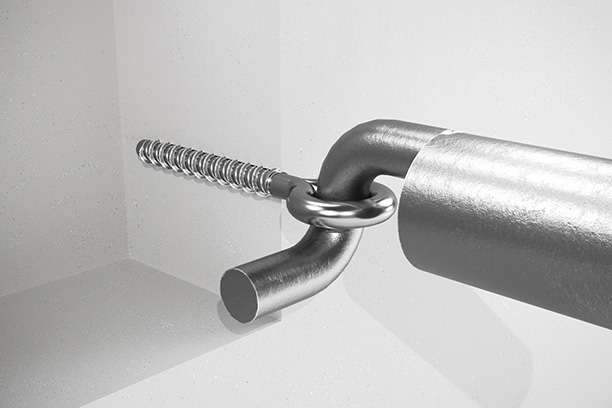

Applications for versions of non-structural installations (ETA 20/0494)

- Fastening of tubes

- Air conditioning conduits

- Electrical trays or wiring systems

- Installations in hollow concrete ceilings

- Installations in hollow-core slab ceilings

Choose the perfect coating according to the corrosion level

| C1 | C2 | C3 | C4 | C5 | |

|---|---|---|---|---|---|

|

|

|

|

|||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

Atlantis C3-H coating: valid for dry indoor conditions (50 years) or in C3-type outdoor environments according to ISO 9223, for a period of 25 years.

Zinc coating: suitable for use in dry indoor conditions (category C1 according to ISO 923), for a period of 50 years.

A4 Stainless Steel: suitable for indoor and outdoor applications, in coastal areas, areas exposed to high pollution levels or areas near roads.

The experiences of professionals who already use INDEX® concrete anchor screws

“As they are so easy to install, I spend 45% less time on installation”.

“These anchors are perfect for temporary installations because they can be completely removed afterwards”.

“They perform better because they support loads up to 100% heavier than expansion anchors”.

“They make my work easier because I can use them in different materials at different depths”.

Learn with us

In this video we explain the types of concrete screws that exist, what they are used for, what their main advantages are and how to install them correctly following the instructions on the technical sheet.

Maximum performance and wide load values

Installation guide

Installation for ETA 20/0046 certified version (installations in cracked and uncracked concrete)

Installation for versions for non-structural installations (ETA 20/0494)