Anchors must be installed in a base material that has the appropriate properties to ensure correct load transfer.

The thickness of the base material is one of the key factors to consider when selecting the most appropriate anchor for each application.

When choosing the anchor, we may come across the following situations:

Base material thickness ≥ 100 mm

In this application, any range of approved Index anchors from the catalogue can be used.

The dimensions of the selected anchor must be taken into account, as large anchor sizes may require concrete thicknesses greater than 100 mm.

Base material thickness ≥ 80 mm

For this application, we have several approved anchoring alternatives:

- MTP-X M8 wedge anchor (ETA-12/0397)

- ANCU+ impact anchor (ETA 24/1214)

- HEHC short female anchor (ETA 14/0068)

- NA impact anchor (ETA 24/0011)

- TH/TFE concrete screw, sizes #5 and#6 (ETA 20/0494)

- SFT concrete screw (ETA 25/0078)

Base material thickness < 80 mm

In this case, we recommend testing the base material to determine the anchor resistance values and to verify that it can withstand the required loads without any type of failure. The resistance of the base material to bending stresses caused by the loads transmitted by the anchors must also be taken into account.

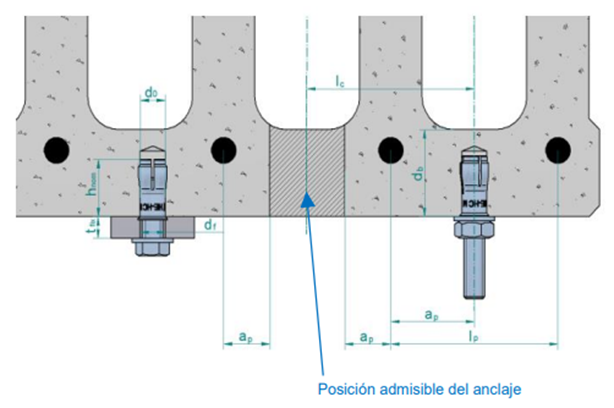

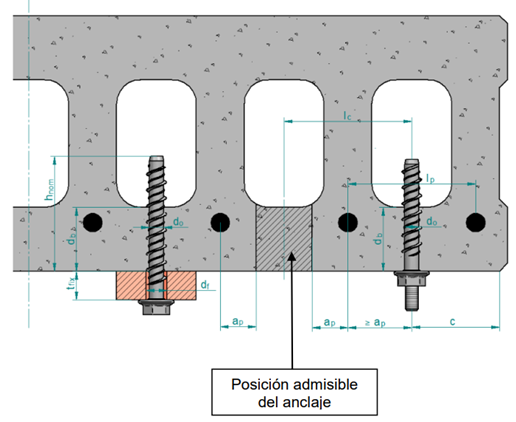

Hollow core slabs with reduced thickness at the bottom of the hollow core

For hollow core slabs, the following ranges of approved anchors may be used:

- HC: is an anchor specifically designed for this application. Minimum thickness at the bottom of the hollow core: 25 mm. ETE 15/0912

- HEHC short female anchor. Minimum thickness at the bottom of the hollow core: 35 mm. ETE 14/0068.

- TH or TF concrete screw. Minimum thickness at the bottom of the hollow core: 25 mm. ETE 20/0494.

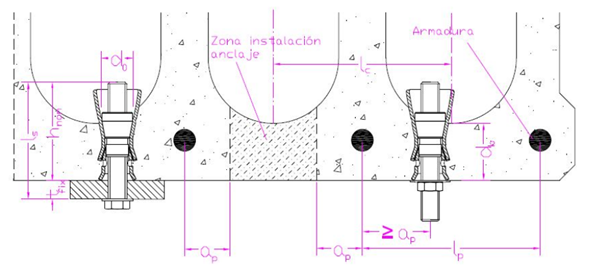

A minimum distance of 50 mm must always be maintained between the anchor and the prestressing tendon.

Last revision: FAQ55 rev0