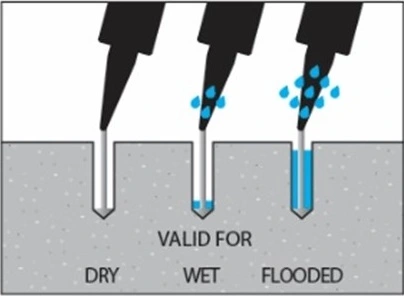

Quando si installano gli ancoraggi, a seconda del principio di funzionamento, le condizioni del foro possono influenzare le prestazioni del prodotto. Innanzitutto, definiamo le tre condizioni indicate nelle normative:

- Foro asciutto: si tratta di un foro in cui l’ancoraggio viene installato in condizioni di assenza di umidità.

- Foro umido: è un foro in cui viene installato un ancoraggio in condizioni di umidità. Ciò significa che all’interno il foro risulta umido al tatto. Di solito ci si imbatte in questa situazione durante il processo di asciugatura di un foro o quando è stato esposto a pioggia leggera.

- Foro allagato: è un foro in cui viene installato un ancoraggio in condizioni di umidità totale, ovvero il foro è pieno d’acqua (da non confondere con un foro sommerso). Questo si verifica solitamente quando l’installazione viene effettuata durante una forte pioggia o dopo una giornata di pioggia intensa, l’installatore può trovare il foro parzialmente o completamente pieno d’acqua.

Una volta che sappiamo come distinguere le condizioni del foro, dobbiamo determinare in che modo influenzano le prestazioni degli ancoraggi. Non ha alcuna influenza sugli ancoraggi meccanici perché tutti, o almeno la maggior parte, sono approvati per le tre condizioni sopra descritte senza influenzare in alcun modo le prestazioni. Al contrario, è molto rilevante per l’installazione e l’indurimento degli ancoraggi chimici.

Alcuni prodotti presenti sul mercato potrebbero non essere omologati per l’installazione in fori allagati, il che significa che non possono essere utilizzati in queste condizioni. Con INDEX, l’unico ancoraggio chimico non omologato per fori allagati è il MOPURE.

Tuttavia, anche se il prodotto è omologato per tutte e tre le condizioni, le sue prestazioni possono essere ridotte se installato in fori allagati. Questa condizione influisce solitamente sulla resistenza di adesione caratteristica o sul coefficiente di sicurezza di installazione del prodotto. In INDEX, l’unico ancoraggio chimico interessato da questa casistica è MO-VH, dove il coefficiente di sicurezza di installazione passa da 1,5 a 2,1.

Infine, un altro aspetto da tenere in considerazione è che sul mercato tendiamo a trovare prodotti con tempi di indurimento che vengono influenzati quando le installazioni vengono effettuate in fori allagati. Questi tempi di solito raddoppiano. Fortunatamente, nessun prodotto INDEX ha tempi di indurimento influenzati dalle condizioni del foro; come tutti gli ancoraggi chimici, sono influenzati solo dalla temperatura del materiale di base.

Ultima revisione: FAQ18 rev0